Assembly lines production

Assembly lines create the optimal balance between labour and machinery and ensure smooth and efficient production and manufacturing.

Assembly lines are created to achieve process and task specialization that can help a production centre scale-up and function at the highest level of productivity. Assembly lines help in the creation of a uniform, standardised high-quality product line that meets the pre-defined criteria.

Types of assembly lines at krisam

Krisam automation, a pioneer in Assembly line productions,brings to your cutting-edge technology gearing you up for a fully-automated assembly line process. Based on the manufacturing process, we, at Krisam automation, design Classic, Automated, Intermittent or Lean assembly lines.

We have expertise in Stand-alone assembly lines, Conveyorized assembly lines and Indexing assembly lines, all of which are curated for different industries and processes.

Parts of assembly lines

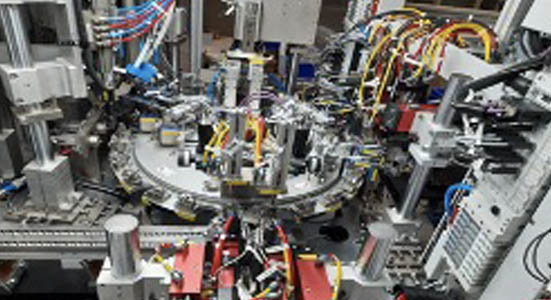

Krisam Automation has various parts of assembly line machines with the key features

Here are the 2 example parts of assembly lines that krisam uses-

- Throttle bodymachine + ECU assembly lines

- Bi Connector Assembly Machine

Key Features for part of assembly line production-

Throttle body+ ECU assembly lines